ApplicationsMiso paste

Task standardization and the prevention of

foreign matter contamination realized by

extracting miso paste from airtight tanks

Fluid name: Miso paste

/ Industry type: Food

Current Problem/Request

Current Problem/Request

Previously, the customer's experienced staff transferred miso paste to cardboard containers from the tanks using shovels. This manual task had the following issues.

- Unless the worker was experienced, the transfer process took too much time.

- There was a risk of foreign matter mixing into the miso.

- The task itself was physically burdensome.

Solution

Solution

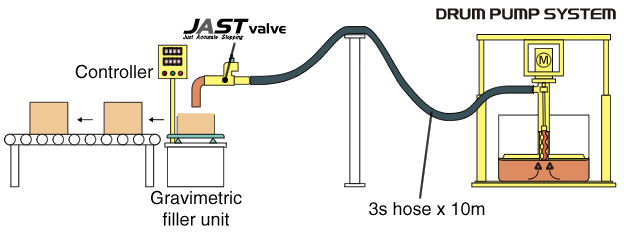

The process of extracting miso paste from the 1-ton tank and filling the containers was automated by introducing a Drum Pump System in combination with a JAST Valve.

Benefits

- The airtight production line enabled the customer to prevent foreign matter contamination and increase the speed of the filling process.

- The automation of the filling process relieved the staff of heavy physical labor and allowed anyone to perform the task.

Flowchart

Related products

Product information

Metered filling machine that combines the outstanding performance of Mohno Pumps with fluid-controlling JAST Valves and controllers.

Product information

Extracts high-viscosity fluid directly from various containers, contributing to the automation and streamlining of processes.

- Food

- Chemical

- Cosmetic

- Electrical machinery